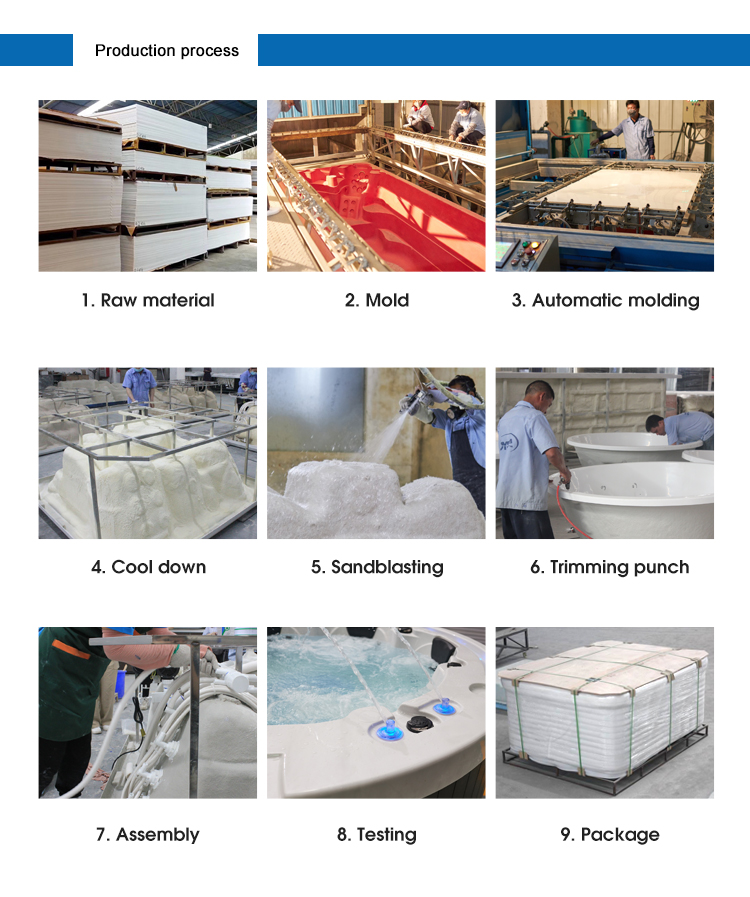

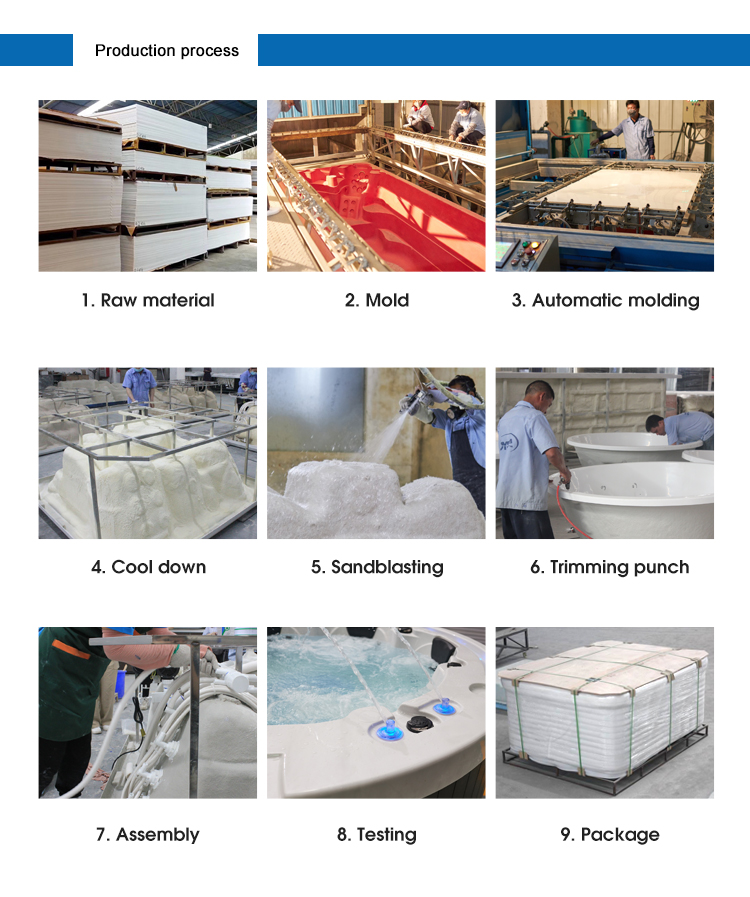

Outdoor hot tub produce procedures

2023-06-25 10:47:57

Outdoor hot tub produce procedures

Bathtub is a kind of sanitary ware product often used in modern bathroom home decoration. The materials used are also very rich. Generally, ceramics and acrylic materials are the majority, and acrylic bathtubs are more energy-saving and environmentally friendly. Therefore, it is very popular and liked by the public. At the same time, acrylic materials can produce bathtubs of various shapes and styles, and high-end ones can be equipped with audio-visual equipment, massage equipment, etc. For this reason, many art tanks and jacuzzis are acrylic. However, the production process of acrylic bathtubs is quite complicated. Now Langdi Sanitary Ware has made a detailed introduction to the production process of acrylic bathtubs for everyone here, hoping to help more people understand and understand acrylic bathtubs.

(1) Molding: Bathtubs, shower room chassis, and backboards of sanitary ware are usually molded with chocolate or composite board-type plastic panels. Due to the complexity of the bathtub and the appearance of the product, the molding depth is deep, and ordinary packaging materials and mechanical equipment are used. It is difficult to meet the technical requirements in use, so choosing the right plate and choosing the right equipment is the basis for excellent product molding.

(2) Plates: Sanitary molded plastic plates mainly use pure acrylic (the chemical name of methyl methacrylate) data or ABS composite materials, as well as recently developed new thermoplastic materials. For the special acrylic board for sanitary ware, due to its excellent surface smoothness, it is equivalent to the wear resistance of aluminum, not easy to brush and easy to clean, and if there is an appearance of accidental scratches, it can be quickly and conveniently changed with a polishing agent.

(3) Mold: In actual production, plastic molded parts are designed and processed according to the designed sanitary ware or sample molding. Aluminum alloy or resin patterns are usually used in plastic molds, aluminum alloy molds have long service life, good process characteristics, and high surface smoothness, but due to high cost and long processing cycle, the application in the production practice of sanitary ware products is limited limits.

(4) Vacuum forming: Cut the sheet in the plastic molding machine according to the requirements, heat and soften the acrylic sheet in the heating furnace at a general temperature of 180 degrees, and the composite board is generally at 140-190 degrees) The softened material is mechanically compacted in the mold , Mold sealing conditions, blown up by compressed air or vacuum suction, the hot plate is stretched and deformed, and the time it takes for the adsorption to the mold wall depends on the cooling fan sheet metal begins to hard shape, after demoulding, take out the product.

(5) Paste: After the blank is formed, it is necessary to strengthen the bonding of the resin. The so-called paste is usually made of unsaturated polyester resin and glass fiber composite material at the bottom of the material, so that the formed product has sufficient viscosity, strength, Pasting methods generally include mechanical spraying and manual dressing. Mechanical spraying is to use a special spray gun to clean the bottom surface of the glass fiber resin and the truncated spray, and then use a manipulator or a manual roller to flatten it. Most of the coatings produced by the current bathroom products are more mechanically pasted. After finishing the application, it is best to put it into a constant temperature curing oven in an environment of 4050 degrees Celsius, and the drying room is completely cured,

(6) Cutting edge: After curing, it sticks to the product and starts to cut the cutting edge. Manual cutting is labor intensive, the quality is difficult to guarantee, and it poses serious hazards to safety hazards.

(7) Drilling: Put the bathtub and other sanitary ware on the hole, if it is on a flat surface, you should try to use machinery for processing, such as drilling, etc. Nozzles, such as the sides of equipment holes, can be processed by machining centers or manipulators (industrial robots), but due to the relatively expensive equipment, most of them are manually operated at present. The abrasive tool hole device should be ground to prevent leakage. Use a special grinding head to grind a ring-shaped flat device on the clay layer deposited on the back of the sanitary ware, which is more conducive to the leak-proof protection of the attachment installation. This process can Can not be ignored.

(8) Support: Sanitary ware supports a variety of materials such as wood, plastic and steel, including the production of stainless steel square tubes. When gluing, the pad or frame is fixed in the correct position of the product, and the bracket is equipped with screws or clamping methods. The quality of the bracket of the sanitary ware affects the safety of the user. Therefore, it is necessary to make the stand strong and stable.

(9) Assembly: water parts and electrical appliances should pay attention to waterproofing to ensure safety. So far the acrylic bathtub has been completed